*****************************************************************************************************************************************************************

SEPTEMBER 2014 UPDATE

*****************************************************************************************************************************************************************

KARL CROWTHER *****************************************************************************************************************************************************************

HYWEL THOMAS *****************************************************************************************************************************************************************

PAUL JAMES *****************************************************************************************************************************************************************

KIER HARDY *****************************************************************************************************************************************************************

KEITH TRUEMAN *****************************************************************************************************************************************************************

GREG BROOKES *****************************************************************************************************************************************************************

PETE JOHNSON *****************************************************************************************************************************************************************

OCTOBER 2014 UPDATE

*****************************************************************************************************************************************************************

PETE JOHNSON *****************************************************************************************************************************************************************

KEITH TRUEMAN *****************************************************************************************************************************************************************

KARL CROWTHER *****************************************************************************************************************************************************************

PAUL JAMES *****************************************************************************************************************************************************************

KIER HARDY *****************************************************************************************************************************************************************

NOVEMBER 2014 UPDATE

*****************************************************************************************************************************************************************

KEITH TRUEMAN *****************************************************************************************************************************************************************

PETE JOHNSON *****************************************************************************************************************************************************************

PAUL JAMES *****************************************************************************************************************************************************************

KARL CROWTHER *****************************************************************************************************************************************************************

DECEMBER 2014 UPDATE

*****************************************************************************************************************************************************************

KEITH TRUEMAN *****************************************************************************************************************************************************************

KIER HARDY *****************************************************************************************************************************************************************

PETE JOHNSON *****************************************************************************************************************************************************************

GREG BROOKES *****************************************************************************************************************************************************************

The two bridge abutments now painted. First, a blackish-grey wash of thinned paint,

which was then wiped off the surface of the stones, leaving just the dark mortar corses. Then the stones

were picked out individually using a mix made up of more Humbrol 121 with varying amounts of 72

(Khaki Drill) and, very sparingly, 93 (Desert Yellow), plus 62 (Leather) being used for for the 'rusty'

looking stones. A final toning down with a weathering mix will now follow to match the existing stonework.

I'm hoping that the bridge deck itself will be completed in time for the layout's appearance at the

This is the site of the old dry dock, which until recently was covered in large piles of

scrap metal and associated processing equipment.... now relocated to another site close by.

A view showing the demolition gang finishing off and getting ready to go home! No doubt

Wimpey will already be planning an ‘exclusive development of modern family homes’ for the site…

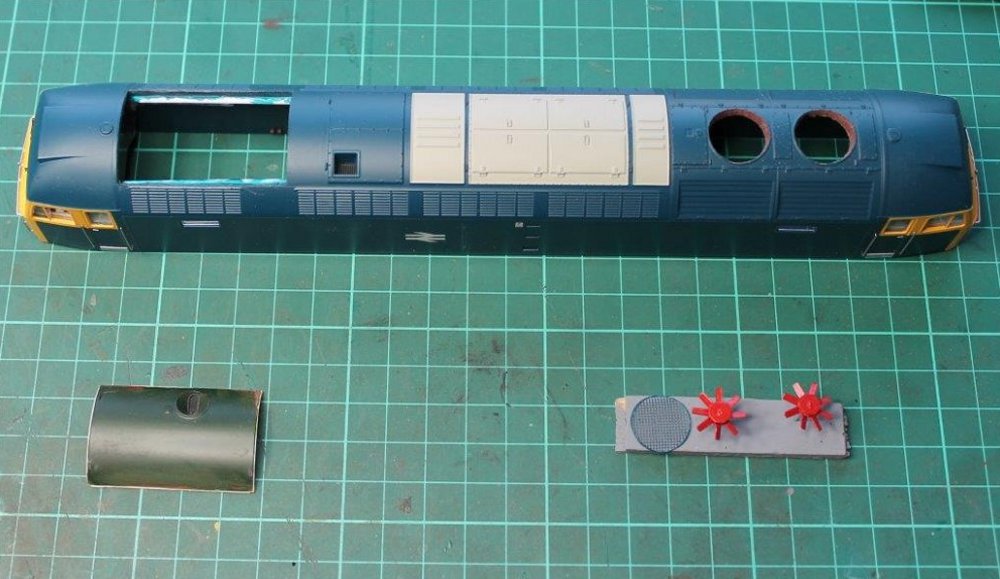

A section of roof from a vacuum braked bodyshell (earlier Heljan version) has been cut

out which features the Spanner boiler exhaust port suitable for dual braked 1516. Roof fan and grill

parts shown ready for fitting.

The roof section containing boiler port fitted in place and ready for painting.

The 'Down' control panel is seen here slotted into the front facia of the layout

(home arrangement), with the rods going through into the baseboard stretchers to provide a solid

fixing arrangement.

The anti-clockwise storage yard panel is located on the exposed steel rods of the

Down panel, giving full control of trains in this direction, and electrically connected underneath

with a 25-way D plug & socket. The existing Gaugemaster controllers connect into each side of the

panel by means of DIN plugs.

The Down panel is now seen slotted into the back of the baseboard at the same

distance from the end (away arrangement), this time with the clockwise storage yard panel being

connected to it, and the anti-clockwise panel connected to the 'Up' control panel at the same

distance from the other end of the layout. Additional slide switches are fitted to the side of the

panel to correct the change in direction experienced with the controllers.

A view of the underside of the panels with the left hand image showing the

anti-clockwise panel plugged in (home), and the right hand image with the clockwise panel connected (away).

Shop fronts have now been added, these being each cut out in one piece from 010 styrene

sheet, then painted with Tamiya’s enamel XF-23 Light Blue, and finally laminated onto the clear plastic

surface.

The bricked pillars dividing the shop fronts were added as each shop face was fixed in

place. The exterior of the building is still to be finished off, including an awning to be fitted above

the small row of shop fronts.

I have added just a couple of people in the corridors of the building to suggest some

life, standing at the windows looking out, probably observing the goings on below in the railway yard.

The model humans were sourced from an inexpensive bulk bag of 100 plastic people, each one has nine

identical siblings! The chosen ones were painted using various enamel paints.

Number 4 was unique in having footsteps at the bottom of the nose sides and grab handles

on the bonnet top, presumably as an experiment for train crew access, hence the OHLE plate.

D218 is one of the latest locos to enter the fleet. Another Bachmann product with

additional detail and weathering to suit the early 1970s period.

The following vehicles were recorded in a southbound parcels train formed mostly of

pre-nationalisation stock. First off is an ex-Southern CCT.

Another ex-Southern CCT in green livery.

A trio of SPV vans (ex fish traffic).

Ex-Southern PMV.

Ex-LNER CCT.

Ex-LMS CCT.

Ex-LMS full brake in blue / grey livery.

Another LMS full brake.

Ex-Southern (Van C) BY.

BR mark 1 Royal Mail stowage vehicles.

Ex-Great Northern full brake.

Once cut from the foam board they have then been bonded onto a thin ply backing

to produce a near life-size replica of the cast-iron street name style found around Gloucester Docks.

End framing details and paint will see this item finished.

The top floor of the R&W Pauls building has windows on all sides so a basic interior

has been made using plastic sheet and section.

Along with discarded sleepers, grounded van bodies were a common feature of the era

modelled. This ex-GWR body has found further use as the P-Way gangers store.

A second example, this time ex-LNER from the Parkside kit, is in use as a lamp and

oil store near the enginemen’s cabin.

With the buildings in position, the dockside industrial scene begins to take shape.

A close-up of one of the pair; Several sizes of brass tube, section and strip

went into constructing the support frames and pipe.

After basic painting, the two pipes were fixed in position on the waterside columns.

The inspiration for the loading pipes - photo taken from the canalside at Gloucester.

Another clutter item for the dockside is this gang-plank,

modelled to an example also found at Gloucester.

The model uses plasticard for the planking, and a combination of brass

wire and etched pieces for the handrails and lifting eyes.

The final item to make – give or take the odd piece of clutter – was the wagon

loading gantry beneath the Downing bridge. This was again made mostly in soldered brass section,

but with plastic tube and cord used for the extending bellows at the bottom of the pipe.

The gantry is pictured again after being fixed in position. The derelict structure

can still be seen within the docks at Gloucester, despite having last seen use more than thirty years

ago. A quest for any photograph of it actually in use for wagon loading remains unsuccessful however.

With assembly of items for the scenic area completed there was nothing left to do

but get the weathering paints out! A start has been made on the tiled roof of the R&W Paul building,

as shown in this view.

Evergreen styrene sheet was used to construct the awning. Both .040” and .010”

were laminated together to allow a rebate for the rain water guttering. Strips of 0.4mm x 0.75mm

were then added to represent the ‘fins’ detail across its roof.

Shops for lease! These will eventually be fitted out with window dressing. Note

the diagonal door handles, made from bent up paper clips.

The DMS bus is currently being detailed inside and out, and later will be on a

regular service in and out of Lesney Park.

The layout is still very much a work in progress, but the mill buildings were

judged to be sufficiently complete for them to be awarded the Tony Jones trophy for best building

on a visiting layout. This was quite an honour as this is a new award being voted on for the very

first time! Evidence of work still to be completed includes detailing of the coal drops, street

furniture and the missing piece of backscene!

This small office building has wandered around the layout over a couple of shows,

but seems to have decided this is the best location for it to be permanently sited! Much work remains

to be done on detailing the ground surface with weeds and other clutter, installation of cosmetic

point levers, plus weathering of the road vehicles etc.

Being only single motored, I've now fitted them with the Hornby Railroad motor bogies. The

Lima pancake motor bogies are then used to double-motor other class 31 in the fleet.

Showing the simple mounting modification, and ease of removal for maintenance.

For further details of previous Hornby Railroad conversions

click here

Following on from the feature last month of parcels vehicles on Shenston Road,

the opportunity was taken to record the Wibdenshaw & Hornsey fleet of NPCCS vehicles. First off is

a pair of BR mark 1 full brakes tagged on the tail end of an Anglo-Scottish sleeper train (Bachmann).

A Ratio kit of an ex-SR bogie B. Certainly not the easist kit to put together

and has suffered some minor warpage in recent years. Hornby produce this vehicle R-T-R now.

A Thompson full brake - previously a BG until the gangways were removed

and plated over. (Bachmann).

An ex-SR CCT labelled as a PMV, which came this way from the Eastwell fleet,

and is an ancient Wrenn model. In the words of Brian Williams it's still a fine piece of plastic

moulding, given the model was originally issued about 50 years ago, and that the CCT below is

recognisable as a K's kit due to the less sharp, and slightly 'rounded' finish to the planking.

A selection of parcels vehicles by Pete Johnson which are regulars at Wibdenshaw

(not much call for them on Canada Street). All feature flush glazing and wire security bars

added as required. (K's kit, ex-SR CCT).

Parkside kit of an ex-LMS CCT.

A BR mark 1 full brake (BG) in blue and grey livery and looking a bit grubby. Built

in the day when it was common practice to splice up from a mix (and shorten) the Tri-ang Hornby BSK

coaches, and stands up well to the Bachmann version.

An ex-GWR syphon G bogie vehicle, Lima based model from the modelling bench during

the late 1970s....and (perhaps?) the time when Lima only did the outside framed version. An age was

spent doing a [mad] convo' filling all the gaps between the framing with overlays, rubbing down,

and then scribing the planking before adding the vents..... totally bonkers really, and probably

should be replaced with the Lima RTR of the inside frame style in the name of accuracy.

Re-worked and detailed Lima GUV.

Ex-LMS GUV (Lima).

Ex-LMS BG (Mainline).

Re-worked and detailed Lima CCT.

Following on from last month's update, the interior of the London Transport

DMS has been finished and furnished with 'Model Power' (USA) figures.

The EFE model reassembled and back in service.

Also on the workbench are these 2 Bachmann class 25 loco's which have been

converted to EM gauge and detail parts added.

During the fitting of bufferbeam detail, I noticed that Bachmann have produced

the multiple-working jumper cables 'mirror fashion', so this has been corrected by cutting off

the cable, and drilling out the plug and gland assemblies.

The modified jumper assembly is shown here to the left, and the original Bachmann

item on the right.

25051 at Lesney Park.

25089 at Lesney Park.

The layout name sign, finished and ready for fitting

The ornate style of fasteners has been copied using bolt heads encased in epoxy

putty, then turned and filed to shape. The end edging is made from some pieces skilfully turned

in hardwood by my mate Dave, then sawn and fitted together.

An example of the inspiration for the sign is seen within Gloucester docks. It

is perhaps slightly unusual for having ‘Street’ as a separate plate, and also with a full stop.

Some of the discarded sleepers pictured previously have had empty

chairs added using C&L parts.

A large packing crate to clutter the dockside - made by re-working the familiar

Hornby wagon load item. For this a milling cutter on a minidrill was used to reduce the heavy

outside bracing, before a general repaint.

Various parts of the layout have now started to have clutter added: – The

S&W works yard……but still no real clues as to what they actually do?!

The torn up track of the dock branch, with lifted sleepers and chairs just left in a heap.

The p-way stores area by the grounded van, with various track maintenance items gently rusting

Weathering of the main buildings has also begun, although still with final blending

to add. The dockside by the Burtons building begins to come to life….

A view looking the other way, under the R&W Paul loading gantry.

At the same time parts are being made ready for taking the show on the road. Most of

the main elements crate-up into three boxes, this is one of the transport frames, made from 10mm ply.

A trial load-up suggests it will all fit in the car…....just!

A Hornby Sentinel shunting locomotive, which I've recently converted to EM gauge

using the original wheels.

Showing the keep plate and wheels removed. Clearances are quite tight, so the

process did involve facing the wheels to make them fit.

The wheels regauged to EM and fitted back into position. Slight tweaking to the

brass pick-ups may be required so they contact the wheel rim.

Keep plate refitted and ready for service.

This month I’ve made a start on a High Level chassis and detailing kit for the

Mainline Class 03 diesel shunter. Work on the body is here just about completed. In addition to the

kit, the air horns, air tanks and conical exhaust were from the A1 Models range, whilst the vacuum

exhauster cabinet was built up from styrene sheet. Replacing all the moulded handrails with 0.3mm

nickel silver wire was a big job, but well worth the effort. I’ve left off the rear step assemblies

for now to help with detailing the cab interior. Painting and numbering as 03371 will be done after

the chassis is up and running.

I’ve also been working on a couple of small shed-type buildings, based on an original

from Halifax Town station. This had three windows, but I’m not sure if this may be too long for the

layout, so I’m also building one with just two windows. Like the other buildings on the layout, walls

and windows have been laser-cut, in this case from 2mm MDF and 0.8mm plywood respectively.

The walls have now been clad with a lower portion of stretcher-bond brick-embossed

Plastikard, plus an upper section of vertical planking, I think from the Evergreen range. The latter,

first had a layer of 10-thou applied underneath so the planks would stand slightly proud of the

brickwork, as in the original structure. Evostick Time Bond was used to glue the styrene parts onto

the MDF, with the doors and windows being cut through and tidied up afterwards with files.

I've been working on the traverser yard lately, as well as testing some recently

acquired Sealion ballast hoppers. Unfortunately though no feature pics on the Sealions

fleet yet, only loaded with ballast thus far and not weathered.

The table is 1140 mm long, and is of plywood and pine timber construction running over

aluminium angle sections at the ends and using ball bearing wheels. Rail is Peco code 75 soldered onto

copper faced strips from C&L.

An additional section off the end end of the table is for the purpose of a loco

release or to store locomotives between movements. These roads are to refuge a locomotive the

length of a class 20 or similar, plus one one guards van, or can hold longer locomotives such as

a class 40. More refuge tracks will be added in due course.

I still have an interest in Australian railways, so this takes up a fair chunk of

my modelling time. Progress on Lesney Park can therefore be intermittent, but a nice

distraction from other projects.... a photo showing one of my Victorian Railways EMD T class 1st

series (T1) with a short train of four wheelers loaded with brown coal. Behind this train can be

seen a further four units I am adding to my fleet awaiting some weathering before they go into

service. The VR T1’s are similar to the British Class 15s, even weighed in at 68 tons. The EMD

model proved very reliable as a maid of all work, and travelled great distances from home depots.

A more close up pic of VR T1 models. Built in Australia under license from EMD,

these were also a U.S. export design, some went to the Kowloon and Canton Railway, and many other

places, and in several incarnations. Some with extended chassis and with C0-C0 or A1A-A1A wheel

arrangements. Their body height from rail level is about the same height as locos on the BR

(obviously aimed at the UK too) the exhaust stack however, would put them well out of gauge.

The latest on the layout front comes in the shape of a few more buildings, bashed

about from various HO scale construction kits and sheets of embossed plastic card.

With a bit of toning down and additional detail added, the orange '50s style building

will hopefully blend into the background.... so you can put your sunglasses away!

With the brickwork enhanced with a darker colour, it is now ready for a mortar wash.

This is one of a pair of Heljan class 47s that I bought over 2 years ago, which have

only just passed into service at Hornsey. D1100 was a Holbeck allocated loco and was a regular at

Kings Cross. Here it's seen heading a 1B66 Cambridge Buffet service.

The other has become 1932 (a Western loco which got about the regions quite

a bit), fitted with ETH in 1970, and losing its steam heat equipment in the process.

A new feature for the waterside area on the layout is this dockyard tug, made from

the Artitec resin model sold by Langley Castings. The level of detail within the crisp resin parts -

most of the hull and deck being a single piece - make for a very quick and easy build of a superb model.

This detail view of the bow shows the slight tweak made to the shape above the deck to

be more typical of a British vessel. The handwheels are from the 51L range, being more finely etched

than the fret supplied with the kit.

A general view of the completed tug after basic painting. The colours chosen seem to

be fairly typical of tugs found at various ports around the UK.

The wagon workshops have also seen some activity this month…..This BR brake van had

been damaged during a recent show, replacement solebar, steps and buffers have been fitted using parts

taken from a spare Airfix kit.

A new wagon type for the fleet is this Dia 2/072 ‘Flat ED’…..which certainly lives up

to its branding! The model was inspired by a chance find at Bridgnorth, SVR, where a wagon of this design

lies largely hidden under locomotive parts awaiting attention.

BR built only 32 of the type, which were similar to an LNER Plate wagon with the sides

removed. The planked deck of the model was scribed in 1mm black plastic, with solebars and brake-gear

adapted from a Parkside blue-spot fish van kit. The chain rings around the edge of the deck were cut

from several scrap Lowfit body mouldings.

Another unusual wagon type also making progress is this Dia 2/002 ‘Arm ET’ 55T armour

plate wagon. This is the longer / heavier cousin of the 40T Arm EL finished a few months ago, and again

makes use of pieces from a Cambrian Models kit. The brake handwheels and shackles are again from the

excellent 51L etched brass range.

TA far quicker project is this ex-GWR ‘Weltrol WH’ from the Mainline/Bachmann model.

Drop in some EM wheel sets, add some 3-link couplings and a couple of route card holders and it’s ready

for weathering……

Paul James has been by the lineside at Shenston Road photographing recent activities.

D8223 & D8229 head a mixed freight past the goods loops next to BSC Shenston Works (both Heljan).

Brush 4 1665 (Heljan), with BR type 2 number 5201 (Bachmann).

Brush type 2 number 5809 (Hornby).

BR Swindon built D9535 heads a short trip freight (Heljan).

English Electric type 4 number D423 (Hornby).

Hymek D7056 hauling bitumen tanks. (Heljan)

Van and bitumen tanks.

BRCW type 2 number 5409 heads a southbound freight (Heljan).

Next up is a trio of Westerns new into service (Dapol) starting with D1005 Western Venturer.

D1028 Western Hussar.

D1054 Western Governor.

And now we step into the TOPS era, with 08951 heading for the steelworks.

Steel coils on the move behind green 40181.

These and other wagon photographs can be found in the Gallery &

Projects section of the website.

Other wagons seen passing through en-route to being finished. This pair of scratchbuilt

Limestone hoppers were started many years ago, and just need small details to finish.... including

removal of cobwebs!

08951 shunting bogie steel wagons in the steelworks.

Ex-Tippler wagons in use for transporting ingot moulds.

08951.